Rockwool Clean Room Panel

Features:

Application:

E-mail: manager@anlaitek.com / admin@anlaitek.com

Phone: +86 18928863810

Keyword:

Category:

Cleanroom Sandwich Panel

leave a message

Product Details

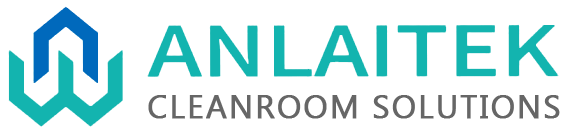

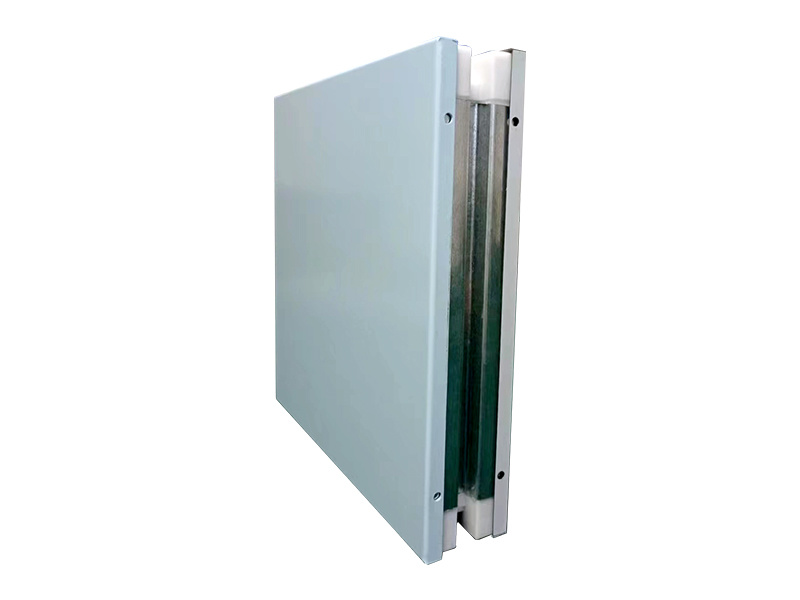

Product Diagram-Rockwool Clean Room Panel

|  |

Product Specification

| Item | 980/1,180 |

| Width | Wall panels 100-9,000, and ceiling panels 100-3,500 |

| Length | 50/75/100 |

| Thickness | 0.4-0.6 |

| Panel thickness | Color-coated steel plate |

| Panel material | Special corner code fixing parts Back plate 0.6mm color-coated plate (or galvanized steel plate) |

| Face coat | PE (polyester), PVDF (fluorocarbon),HDP(high durable polyester) |

| Core material | Rockwool (bulk capacity:100-120kg /m³) |

| Thickness of keel | 0.6-0.8 |

| Corner | 0.5 (Galvanized) |

| Resist film | 60μm /80μm |

Features

1. Wide range of applications

The product can be applied to the factory floor with clean requirements such as pharmaceutical, electronics and food.

2. Good physical and chemical properties

The steel surface of rock wool purification board product is baking coating or zinc coating, stainless steel plate, so the corrosion resistance is very good; the weight of the plate is 18-20kg/㎡, the core material has fireproof insulation (fire resistance limit: 30min), water (≥ 98%) performance; all side joints have flush butt joints, aluminum profiles, excellent product performance, 1.1KN/㎡ flexural load, high strength, impact resistance and shock resistance.

3. Convenient construction and installation

Can be customized, on-site splicing, easy to install; the clean board can directly open the hole and reserve the line pipe, improve the installation efficiency, and can be disassembled many times, the comprehensive benefits are very significant.

Case Presentation

Advantages

1. High strength, high density rock wool board inside, 4 to 5 times stronger than ordinary rock wool strip.

2. Produced by the world's first clean board automatic production line. Compared with the traditional clean board manual production line, the automatic production line improves production efficiency by 6-8 times and saves time.

3. Used for reinforcement of the hole and the pipeline box is assembled in the factory in the factory, which effectively reduces the secondary pollution during use, especially in the operating room.

Install Method

The mechanism cleanroom panel adopts a T-Grid Ceiling tiles Systems which are connected by a cleanroom ceiling (also known as a wall panel) and a T-shaped aluminum profile.

The resistance to bending and adhesion, stable quality, people and equipment can walk on it. The ceiling system can be perfectly connected with the modular cleanroom panel system to ensure that the width of the cleanroom ceiling system connection gap and the wall gap are consistent, which improves the aesthetics of the cleanroom.

Patent Certificate

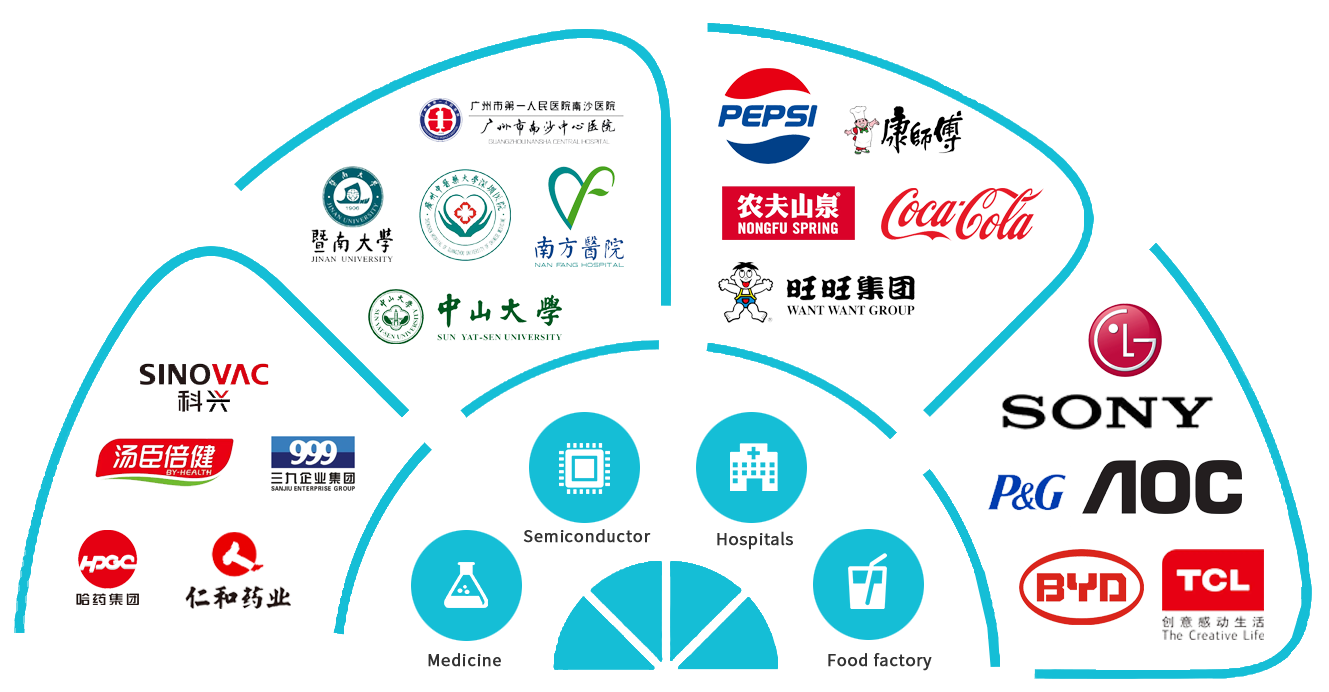

Our Partners

FAQ

What is the minimal order quantity for placing order?

We can accept sample order, only one is OK.

In addition to 50mm thick sandwich panel, can your doors integrate with other walls?

Yes, our door frame can be customized to fit for different walls of different thickness from 50-200mm, like mansonry wall.

In addition to this fire exit door, what other cleanroom doors do you have?

In additon to this fire exit door, we have PCGl steel door, stainless steel door, HPL door, sliding door, fast speed rolling door.

What's the lead time for my order?

lf your order is less then 100 doors, the lead time is within 15 days after receiving advance payment.

What l need to know before placing order?

Before placing order, we kindly have your attention to the following:

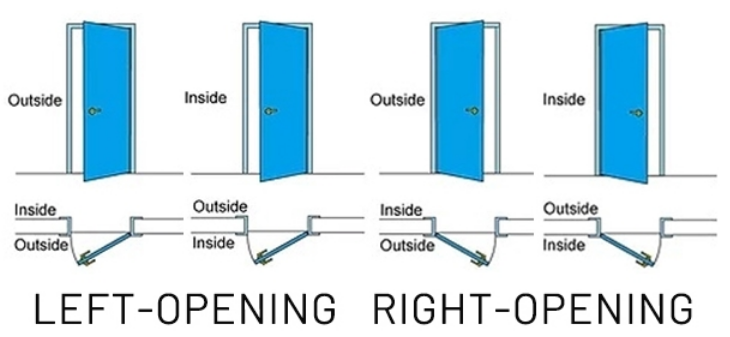

1. Door Opening Direction

Note: In order to avoid misunderstanding, we stongly suggest you to send us a sketch or a layout plan of the doors on whichthe door opening directions are indicated.

2. Door Size

Our standard door sizes refer to the door frame size, NOT door leaf size, NOT clear go-through size.

Related Products

Leave a Message